Rebar Stirrup Bending Machine GF36

GF36 Rebar Stirrup Bending Machine shapes 6–32mm steel bars with strength and precision. Its industrial design and global voltage compatibility make it ideal for serious reinforcement work.

Rebar Stirrup Bending Machine GF36

Reinforcement Stirrup Bender GF36 for 6–32mm Rebar | Heavy-Duty Steel Bar Stirrup Bending Machine

Product Overview – Powerful Stirrup Forming Equipment for Concrete and Precast Steel Projects

The Rebar Stirrup Bending Machine GF36 is built to handle 6mm to 32mm steel rebar, delivering robust and precise stirrup shaping for mid-to-large-scale construction projects. It is widely used in precast concrete yards, bridge sites, metro tunnels, and other projects requiring consistent bar shaping performance.

Designed for high efficiency and operational ease, the GF36 is the perfect balance between strength, versatility, and durability.

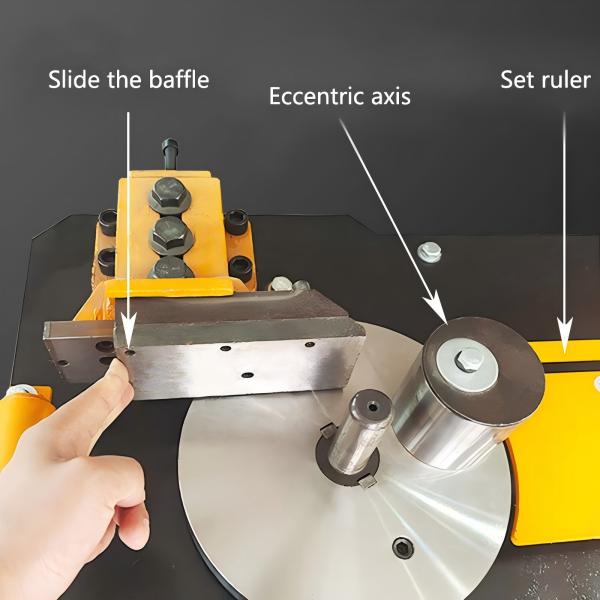

Smooth Operation with Enhanced Accuracy

Equipped with a reinforced rotating disc, hardened bending pins, and angle-adjustable control knobs, the GF36 ensures repeatable bending from 0° to 180°. This machine uses a high-performance copper-core motor to generate stable torque, reducing steel rebound and ensuring uniform stirrup shapes across batches.

Its sealed gearbox system minimizes wear and operational noise, while dual-operation modes (foot pedal & hand control) provide operator flexibility and enhanced safety.

Built Tough for Global Job Sites

The GF36 stirrup bending machine features a heavy-duty frame, constructed to absorb vibration and resist deformation under load. It moves easily thanks to industrial-grade caster wheels, making repositioning effortless. It supports both 220V and 380V, 50Hz/60Hz voltage systems, making it a ready-to-export product for use in international construction markets.

Whether you’re fabricating stirrups on-site or in a dedicated rebar shop, the GF36 offers the performance and durability to keep production moving.

Key Features of Rebar Stirrup Bender GF36

-

Bends 6–32mm steel bars into accurate stirrup forms

-

Strong motor and disc system for high-output operation

-

Two control options for flexible working conditions

-

Voltage adaptable for use in export or local projects