Rebar Stirrup Bending Machine GF25

GF25 Rebar Stirrup Bending Machine bends 6–22mm steel bars into various stirrup shapes efficiently. Ideal for structural reinforcement, built with rugged steel and global voltage support.

Efficient Stirrup Bending Machine for 6–20mm Bars | Industrial-Grade Rebar Stirrup Former GF25

Product Overview – Versatile Stirrup Bender for Construction Reinforcement Fabrication

The Rebar Stirrup Bending Machine GF25 is a high-performance solution for producing stirrups from 6mm to 22mm rebar. Designed for structural steel processing, this machine can rapidly form a wide variety of stirrup shapes—squares, rectangles, trapezoids, and custom angles—used in concrete columns, beams, slabs, and footings.

Thanks to its industrial copper motor and precision bending mechanism, the GF25 stirrup former ensures repeatable performance in both onsite and prefab environments.

Powerful Output and Easy Angle Customization

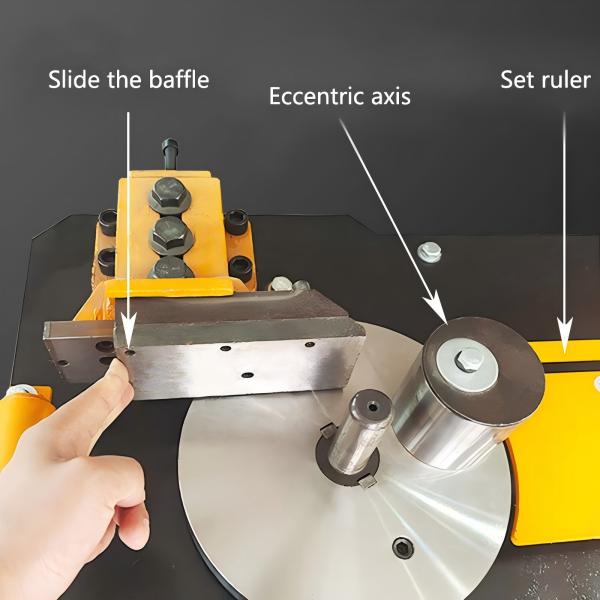

Equipped with an expanded bending plate, dual adjustable stoppers, and programmable angle selectors, the GF25 delivers consistent bends up to 180° without bar deformation. The machine’s sealed gearbox operates with low noise, minimizing maintenance needs over time.

Operators can switch between foot pedal control and manual operation, making it safer and more adaptable across different construction settings.

Rugged Frame with Export-Ready Voltage Options

The GF25 rebar stirrup bender is built from reinforced welded steel, offering durability under high-torque workloads. It includes solid transport wheels for easy mobility across project sites. Additionally, the machine supports 220V or 380V (50Hz/60Hz) input, fully compatible with international jobsite requirements.

Its efficiency and precision make it an ideal choice for contractors, steel fabricators, and rebar processing centers worldwide.

Key Features of Rebar Stirrup Bending Machine GF25

-

Bends 6–22mm bars into stirrups with excellent accuracy

-

Fast shape switching for square, rectangular, and custom stirrups

-

Reliable motor and low-maintenance internal system

-

Ready for global export with flexible power input