Rebar Cutting Machine GQ60 (Round knife)

GQ60 Round Knife Rebar Cutter handles 6–50mm steel bars with low resistance and smooth rolling-shear. Suitable for heavy construction and global export projects.

Ultra-Capacity Round Blade Rebar Cutter for Precision Heavy Bar Processing

Product Overview – Rolling-Shear Rebar Cutting Equipment for 6–50mm Bars

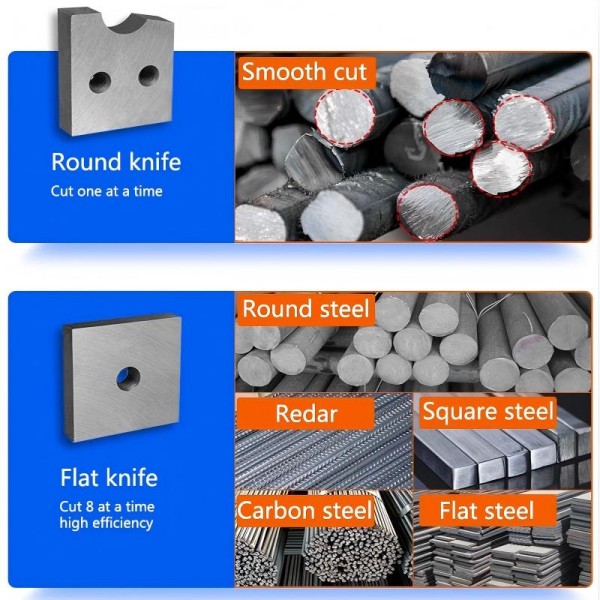

The Rebar Cutting Machine GQ60 (Round Knife) delivers powerful and precise cutting for 6–50mm steel bars. Construction teams rely on this machine to process carbon steel, round bars, and ribbed bars with ease. The round knife design uses a rolling-shear movement. As a result, it reduces resistance and allows for smoother, faster cuts.

Contractors use this model in large-scale projects like bridges, tunnels, ports, and structural steel works.

Rolling Knife Design for Cleaner Results

The round blade rotates during the cutting motion. This creates a gliding action that applies less direct impact on both blade and steel. Therefore, the machine produces cleaner edges and extends blade life.

A high-efficiency copper motor powers the machine. It delivers strong torque across long shifts without overheating. In addition, the internal gearbox ensures stable torque transmission. Operators experience minimal vibration and lower energy consumption.

Rugged Frame and Easy Maintenance

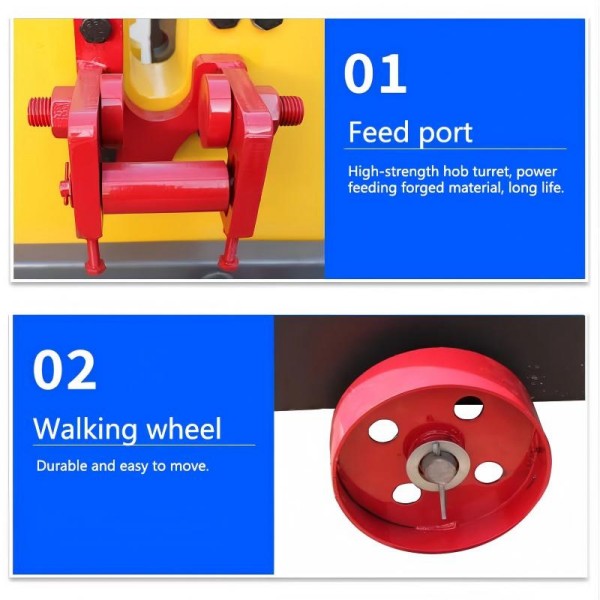

A reinforced cast iron frame supports the GQ60’s durability. Workers can move the machine across rough job sites using the heavy-duty wheels. A long-handled lever provides safe, hands-on control.

In addition, the machine’s top cover opens easily. Technicians can inspect or change blades without removing extra panels. This design shortens downtime and improves work efficiency.

Built for Export and Continuous Operation

The Rebar Cutting Machine GQ60 (Round knife) supports global voltage standards (220V/380V, 50Hz/60Hz). Construction companies around the world trust this model for demanding steel cutting operations.

Key Benefits of GQ60 Round Knife Cutter

-

Cuts 6–50mm steel bars with smooth rolling-shear precision

-

Extends blade life and reduces cutting effort

-

Withstands long hours in high-output construction environments

-

Export-ready with multi-voltage support