Automatic Stirrup Bending Machine STWQ4-14C

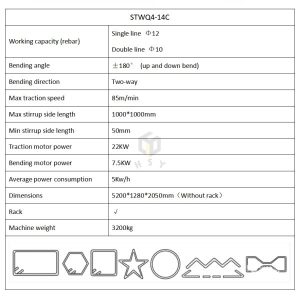

STWQ4-14C automatically bends 4–12mm coiled rebar into stirrups using intelligent CNC control and dual servo motors. Reliable for continuous, industrial-grade use.

Automatic Stirrup Bending Machine STWQ4-14C

STWQ4-14C Intelligent CNC Stirrup Bender | Coil Rebar Processing Equipment for 4–12mm Steel Bars

Product Overview – Designed for Continuous, Smart Rebar Stirrup Fabrication

The Automatic Stirrup Bending Machine STWQ4-14C delivers reliable, high-speed processing for 4–12mm coiled rebar, combining intelligent CNC control, automatic feeding, and dual-head bending technology. This model is tailored for large-scale rebar workshops, precast component manufacturers, and contractors aiming for minimal downtime and high production consistency.

Its advanced electronics and ergonomic design reduce human error, improve operator efficiency, and support a wide range of stirrup configurations.

Precision, Stability, and Shape Diversity at Scale

STWQ4-14C operates with multi-axis servo control, enabling fast yet accurate forming of square, rectangular, triangle, and polygonal stirrups. The user-friendly touchscreen control panel stores multiple shape presets, simplifying order switching and ensuring minimal setup time.

The improved wire feeding path, paired with a refined straightening module, helps reduce steel bar twist and guarantees uniform output—even under continuous operation.

Compact Footprint, Built for Global Export and Installation

Despite its industrial-grade performance, the STWQ4-14C maintains a compact structure that fits seamlessly into workshop lines or mobile production units. The frame includes anti-fatigue design, self-check fault diagnostics, and centralized lubrication, ensuring long-term reliability.

Compatible with 380V/50Hz three-phase power and customizable for overseas voltages, this machine meets global standards for rebar forming systems.

Key Features of STWQ4-14C Rebar Stirrup Bending Machine

-

Forms stirrups from 4–12mm coil rebar with CNC precision

-

Dual servo-controlled bending system for fast and clean angles

-

Touchscreen programming with multi-shape memory

-

Energy-efficient operation with low maintenance demands

-

Built for export, durable for high-volume use